Final PP flakes moisture between 3%-5%.

Use world famous brand parts,like Siemens motor,Fuji Inverter,SKF bearing,SUS 304 stainless steel, SKD-11 blades,etc.

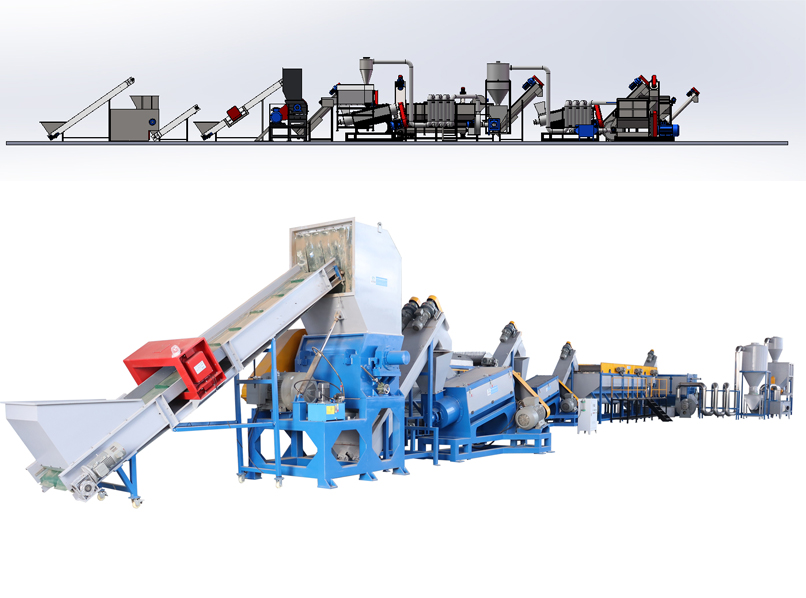

Our PP Woven Bag Big Bag Washing Line is a complete recycling line for crushing washing and drying of PP woven bags,PP jumbo bags,PP big bags,PP sacks,PP waste cement bags, etc. Washing and cleaning of PP bag is different from washing of PE film. Our PP Woven Bags Washing Line is designed with high output,energy saving,stable running features.

Our PP woven bag big bag crushing/washing/squeezing/drying recycling line is mainly designed to deal with waste plastic materials like PP woven bag, PP jumbo big bag, materials of LDPE agriculture film, LLDPE wrapping stretch film also supports. offers pp woven bag recycling solutions that are high output and low energy consumption. As a top manufacturer of plastic recycling manufacturer, Retech Machinery offers PP woven bag recycling machines solutions with high output and low energy consumption.

The whole PP woven bag washing recycling machine process includes shredder, water rinsing, friction washing, drying and washing system, the final flakes humidity will be less than 5%, it could send to our compactor granulating machine to make new granules directly. We could supply PP PE film bag washing line between 300kg/hr to 2000kg/hr. Although our standard plastic woven bag recycling lines are sufficient for most facilities, to meet your specific needs, custom lines with additional machinery are warmly welcomed.

LDPE agriculture film,LLDPE stretch film,PP woven bag,PP jumbo bag scrap.

LDPE agriculture film

LLDPE wrapping film

PP woven bag

PP jumbo bag

After process

After process

After process

After process

| Model | Power | Water | Capacity |

| RM300 | 85kw/h | 4-6 t/h | 300kg/h |

| RM500 | 155kw/h | 6-8 t/h | 500kg/h |

| RM1000 | 320kw/h | 8-10 t/h | 1000kg/h |

| No | Equipment name | Quantity |

| 1 | PP Big Bag Shredder | 1 |

| 2 | Wet PP film bag crusher | 1 |

| 3 | High speed friction washer | 1 |

| 4 | PP PE Film floating washer | 1 |

| 5 | Hot floating tank | 1 |

| 6 | PP PE cold washing tank | 1 |

| 7 | Friction washer | 1 |

| 8 | PP Woven Bag Squeezing machine | 1 |

| 9 | Storage hopper | 1 |

| 10 | Electric panel | 1 |

Final PP flakes moisture between 3%-5%.

Use world famous brand parts,like Siemens motor,Fuji Inverter,SKF bearing,SUS 304 stainless steel, SKD-11 blades,etc.

We are a manufacturer which producing the machines by ourselves.

Our warranty year is one year. During the period, we provide you spare parts free of charge asap. But the technical guide is forever.

We will send the instruction manual and videos to you,your workers can install the machine accorded to it. If the situation is ok, we can arrange our engineer to your factory, who will teach your labors how to install machines.

We will provide maintenance instruction, it will mark the oil model and time. And how many times you should check the machines. Any problems about machines, you can ask us anytime.

We promise our machine’s quality. Also we will prepare enough spare parts from the beginning for using urgently. Some vulnerable parts(blades), we will suggest you to buy. The last way,we send you spare parts by DHL.

We will send you manuals for product maintenance and how to solve common problems. By the way, you can contact with us, we will try our best to teach you by instruction book or video.

We provide 12 months’ warranty period usually.In this Period, any machine’s quality problem,we will send spare parts soon by DHL. We will do our best to teach your worker how to change the spare parts by video or instruction.

We will online 24 hours every day, You can contact with us anytime. Our engineer will send you machine maintenance manuals.