This machine integrates crushing, extrusion and granulation, which can effectively recover materials, increase production capacity and save floor area. Especially suitable for BOPP, HDPE, LDPE, PET, PA film, fiber and plastic bag recycling.

Film Crushing/Compacting

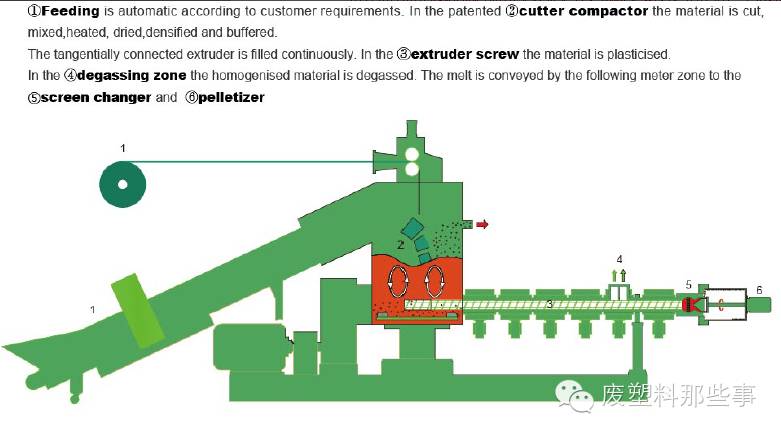

PP PE film, fiber and other raw materials are sent into the film breaking machine by conveyor, the operator does not need to carry out raw material weight. As the feed quantity and speed are controlled by the set motor current of the film breaking machine, the feed quantity of the film breaking machine can be adjusted automatically, and the melt pressure of the extruder can be kept the same. If the raw material is drum film, the film can also be fed into the film breaker by roller feeder (optional configuration).

After the raw material is fed into the film breaker, it is cut, preheated, dried and granulated in the same process.

Extrusion

After the material is broken film and granulated, the material is fed into the extruder for plasticizing and mixing by rotating cutting tool and centrifugal force.

Because of the design of the solute breaking machine, the raw material can stay longer in the breaking membrane cylinder. This design promotes better compacting and more uniform temperature of the pellet feedstock fed into the extruder, which also increases production.

Filtering granulation

After plasticizing and mixing of raw materials in extruder, natural degassing or vacuum degassing process can be carried out according to demand; The impurities are then filtered through the oil pressure mesh changer and the next granulation operation is carried out. Automatic "self-cleaning filter" can also be installed according to raw materials and operation requirements.

Melt glue through the water ring granulator, namely the production of uniform cylindrical or flat plastic particles. Then through the continuous dehydrator for dehydration and drying; Then the plastic particles are sent to the cyclone separator or bin by the windmill for packaging operation.