Plastic regeneration granulation processing process, melting, filtering, extrusion pelletizing is three basic process, the filter link play a crucial role, because it with the clean degree of renewable particles, in addition to that there is a close relationship between utility and value, also involves the Labour strength of workers in the process of granulation, the safety coefficient as well as to the screen and raw material consumption.

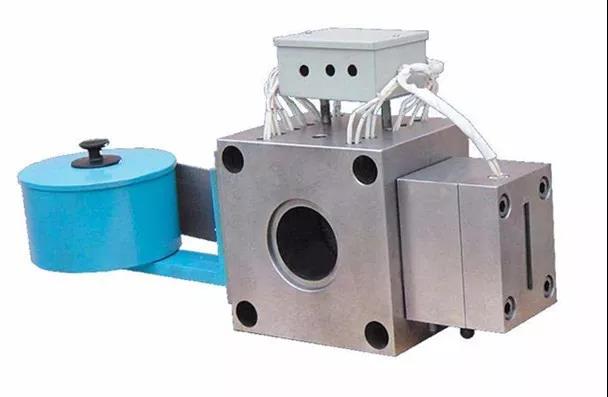

Filter of traditional granulator

The research of pelletizer filter has gone through the following process: from the traditional manual mesh changer to the electric mesh changer, from the electric single position mesh changer to the double position mesh changer, and then to the hydraulic driven double position mesh changer.

The research and design of traditional screen changer focus on two aspects: one is to increase the unit filter area as much as possible to prolong the time of screen blocking and screen replacement; The second is to reduce the labor intensity of the network as much as possible or solve the impact of the interruption of production in the process of network change, so as to develop the filter die head of electric, hydraulic and pneumatic as the driving force of network change.

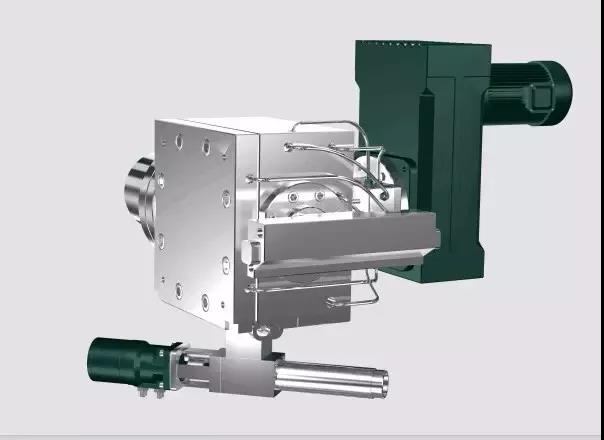

No screen granulator filter

No screen filter is called no mesh mold head, no filter filter, non-stop automatic spit miscellaneous mold head, a plastic granulator filter without the installation of a filter.

Working principle: the equipment is equipped with alloy steel cone filter sleeve, filter sleeve has anti-clogging unidirectional melt filter microhole, play a key role in allowing molten plastic through, blocking impurities. In addition, the filter system is equipped with synchronous operation of impurity removal scraper, work, melt plastic through the fine hole, impurities and dirt in the inner wall of the filter sleeve; Impurities are removed at the speed of 3-5 revolutions per minute by the impurity removal scraper and pushed to the impurity storage cavity by the impurity removal screw at a uniform speed.

Advantages: improve the use efficiency of recycled plastic extruder, reduce labor intensity of workers, energy saving and environmental protection, avoid the traditional filter consumption, high cost, incineration after use will produce secondary pollution and other shortcomings. With automatic discharge of miscellaneous, no need to change the network, environmental protection, electricity saving, increase output, strengthen plasticizing, reduce labor, simple control and other advantages.

RETECH is a professional manufacturer for plastic recycling machines, we supply:

(1) PP PE film washing recycling line

(2) PET bottle recycling machine

(3) HDPE PP bottle cleaning plant

(4) PE PP film compactor pelletizing machine

If any interest of plastic recycling machinery,please contact us to get a solution.