Final moisture below 1%. Granules are uniform and in good looking.

Use world famous brand parts,like Siemens motor,Fuji Inverter,SKF bearing,Mesutronic metal detector,38CrMoA1A bimetal screw,etc.

RCSJ 130 PP woven bag shredder-compactor integrated pelletizing recycling machine is aim to processing waste plastic like PP woven bag,PP non woven fabric,PP long silk tape,PP fish net,etc. A shredder in front of pelletizing line will pre-cut the big bag or long fabric plastic into small scrap. It will improve the feeding into compactor for deep cut and agglomeration. Single or double stage pelletizing system with vacuum degassing vent could melt the material and discharge moisture or gas. Self cleaning automatic laser filter screen is a good choice to save labor cost. Two times filtration is much better to get the best quality granules. A die face or strand cutting system with horizontal or vertical water ring cut way. In the end,you will get a clean,dry,strong pellets for next step like film blowing,moulding injection,etc.

Our RCSJ series shredder-compactor integrated pelletizing recycling line is aim to processing waste plastic like PP woven bag,PP non woven fabric,PP long silk tape,PP fish net,etc. A single shaft shredder in front of pelletizing machine will pre-cut the big bag or long fabric into small scrap. It will help the material feeding into compactor for deep cut and agglomeration. Single or double stage pelletizing system with vacuum degassing could melt the material and discharge moisture or gas. Self cleaning automatic laser filter screen is a good choice to save labor cost. Two times filtration is much better to get the best quality granules. A die face cutting system with horizontal or vertical water ring cut way. In the end,you will get a clean,dry,strong pellets for next step like film blowing,plastic injection,etc.

The final granules are uniform after processing by our Shredder-Compactor Integrated Plastic PE Film PP Woven Bag Recycling Pelletizing Line.

We are a manufacturer specialize in plastic recycling equipment, we provide professional customized plastic recycling solutions. We can design PP woven bags and non-woven fabric recycling granulation lines according to your specific demand, all the recycling machinery has been debugged , you can use our pp woven recycling machines with confidence.

PP Woven Bag,Washed PP Jumbo Bag Scrap,PP Non Woven Fabric,Other Soft Plastic Like PE OPP CPP BOPP film,PS foam,PP Raffia Recycling,etc.

Material shapes: film, bag, (PE, PP) regrind

Material types: rolls, loose, bundled

PP woven bags

PP washed scrap flakes

PP crushed scrap

PP non woven fabric raffia

After process

After process

After process

After process

| Model | Screw Dia | L/D | PE (kg/h) | PP (kg/h) |

| RCDJ85 | 85mm | 33 | 180-220 | 160-200 |

| RCSJ85/100 | 85/100mm | 33:12 | ||

| RCDJ100 | 100mm | 33 | 260-320 | 220-280 |

| RCSJ100/120 | 100/120mm | 33:12 | ||

| RCDJ130 | 130mm | 33 | 450-550 | 360-420 |

| RCSJ130/150 | 130/150mm | 33:12 | ||

| RCDJ160 | 160mm | 30 | 650-750 | 500-600 |

| RCSJ160/180 | 160/180mm | 30:10 | ||

| RCDJ180 | 180mm | 28 | 800-1000 | 650-800 |

| RCSJ180/200 | 180/200mm | 28:10 |

PP Woven Bag Recycling Pelletizing Line Workflow:

PP Woven Bag → Shredder → Compactor → Mother Extruder → Hydraulic Screen Changer → Baby Extruder → Hydraulic Screen Changer → Die Face Cutting System → Water Cooling Tank → Dehydrator → silo storage

| Details | Equipment name | Function |

|

Belt conveyor with metal detector | Equipped with a metal detector to remove the metal material and sends plastic waste to the compactor |

|

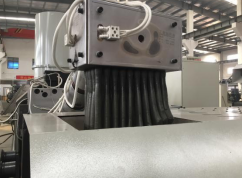

Shredder Compactor |

Pre-cut by shredder.Automatic feeding system. Compactor cutter to improve feeding performance |

|

Mother extruder | Specially designed screw structure to melt pre-compacted materials, has better melting performance and higher output |

|

Baby extruder | |

|

Hydraulic screen changer | With pressure sensor to warning the operator to changing nets |

|

Die face cutter |

Die face cutting or strand noodle cutting optionally. The cutting speed is controlled by invert |

|

Water cooling flume | Made of stainless steel, in L shape cooling |

|

Dewatering machine | Vibration dryer combined with horizontal type centrifugal dryer to get well dried final granules |

|

Vibrator screen | Made of SUS 304, with double layers in 10mm and 2mm(to select pellets) |

|

Packaing silo | Made of stainless steel SUS304 and with hocks for big bags |

Final moisture below 1%. Granules are uniform and in good looking.

Use world famous brand parts,like Siemens motor,Fuji Inverter,SKF bearing,Mesutronic metal detector,38CrMoA1A bimetal screw,etc.

We are a manufacturer which producing the machines by ourselves.

Our warranty year is one year. During the period, we provide you spare parts free of charge asap. But the technical guide is forever.

We will send the instruction manual and videos to you,your workers can install the machine accorded to it. If the situation is ok, we can arrange our engineer to your factory, who will teach your labors how to install machines.

We will provide maintenance instruction, it will mark the oil model and time. And how many times you should check the machines. Any problems about machines, you can ask us anytime.

We promise our machine’s quality. Also we will prepare enough spare parts from the beginning for using urgently. Some vulnerable parts(blades), we will suggest you to buy. The last way,we send you spare parts by DHL.

We will send you manuals for product maintenance and how to solve common problems. By the way, you can contact with us, we will try our best to teach you by instruction book or video.

We provide 12 months’ warranty period usually.In this Period, any machine’s quality problem,we will send spare parts soon by DHL. We will do our best to teach your worker how to change the spare parts by video or instruction.

We will online 24 hours every day, You can contact with us anytime. Our engineer will send you machine maintenance manuals.