Maximum line velocity: 180m/min.

Use world famous brand parts,like Siemens motor,Fuji Inverter,SKF bearing,38CrMoA1A bimetal screw,etc.

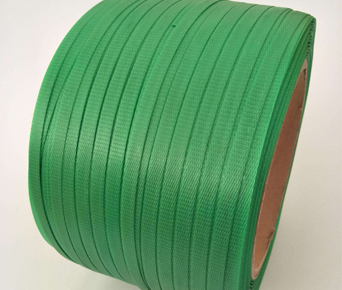

PP packaging belt tape production machine is used to make PP packing strap. Due to the strapping belt with good plasticity, strong tensile strength, bending resistance, light weight and convenient use is widely used in various fields

Our Plastic PP packaging strap tape belt production line is designed for making PP packing strap with good plasticity, strong tensile strength, bending resistance, light weight and convenient features.

PP packing tape production line, equipped with automatic winding machine, the production of packing tape products, not only high strength, small bending, suitable for automatic packing machine packaging, greatly improve production efficiency.

PP packing tape production line.

PP Pellets

PP Pellets

PP Pellets

PP Pellets

PP Tape

PP Belt

PP Strap

PP Tape

| Model | Screw Dia | L/D | Width | Thickness |

| RSP65 | 65mm | 25 | 8-15mm | 0.6-1mm |

| RSP65 | 65mm | 28 | ||

| RSP70 | 70mm | 25 | 8-15mm | 0.6-1mm |

| RSP70 | 70mm | 28 | ||

| RSP80 | 80mm | 25 | 8-15mm | 0.6-1mm |

| RSP80 | 80mm | 28 | ||

| RSP90 | 90mm | 25 | 8-15mm | 0.6-1mm |

| RSP90 | 90mm | 28 | ||

| RSP100 | 100mm | 25 | 8-15mm | 0.6-1mm |

| RSP100 | 100mm | 28 |

| No | Equipment name | Quantity |

| 1 | Screw conveyor | 1 |

| 2 | Ration feeder | 1 |

| 3 | Main extruder | 1 |

| 4 | Water Cooling Tank | 1 |

| 5 | Dryer | 1 |

| 6 | Embossing machine | 1 |

| 7 | Tape handler | 1 |

| 8 | Vibrator | 1 |

| 9 | Rod coiling machine | 1 |

| 10 | Auxiliary equipment | 1 |

Maximum line velocity: 180m/min.

Use world famous brand parts,like Siemens motor,Fuji Inverter,SKF bearing,38CrMoA1A bimetal screw,etc.

We are a manufacturer which producing the machines by ourselves.

Our warranty year is one year. During the period, we provide you spare parts free of charge asap. But the technical guide is forever.

We will send the instruction manual and videos to you,your workers can install the machine accorded to it. If the situation is ok, we can arrange our engineer to your factory, who will teach your labors how to install machines.

We will provide maintenance instruction, it will mark the oil model and time. And how many times you should check the machines. Any problems about machines, you can ask us anytime.

We promise our machine’s quality. Also we will prepare enough spare parts from the beginning for using urgently. Some vulnerable parts(blades), we will suggest you to buy. The last way,we send you spare parts by DHL.

We will send you manuals for product maintenance and how to solve common problems. By the way, you can contact with us, we will try our best to teach you by instruction book or video.

We provide 12 months’ warranty period usually.In this Period, any machine’s quality problem,we will send spare parts soon by DHL. We will do our best to teach your worker how to change the spare parts by video or instruction.

We will online 24 hours every day, You can contact with us anytime. Our engineer will send you machine maintenance manuals.