PP woven bag crusher is used to crush plastic film, LDPE agricultural film, PP woven bags and other light soft materials, flat knife type plastic crusher has a faster crushing efficiency,it can effectively solve the problem of ordinary plastic crusher cutter, through the screen of different aperture, you can get different sizes of materials. The PP woven bag crusher adopts the relative flat knife distribution, which can effectively solve the problems of traditional plastic crusher, sticking material and breaking immovable, and solve the output problem of poor efficiency.

PP woven bag crusher is used to crush plastic film, LDPE agricultural film, PP woven bags and other light soft materials, flat knife type plastic crusher has a faster crushing efficiency,it can effectively solve the problem of ordinary plastic crusher cutter, through the screen of different aperture, you can get different sizes of materials. The PP woven bag crusher adopts the relative flat knife distribution, which can effectively solve the problems of traditional plastic crusher, sticking material and breaking immovable, and solve the output problem of poor efficiency.

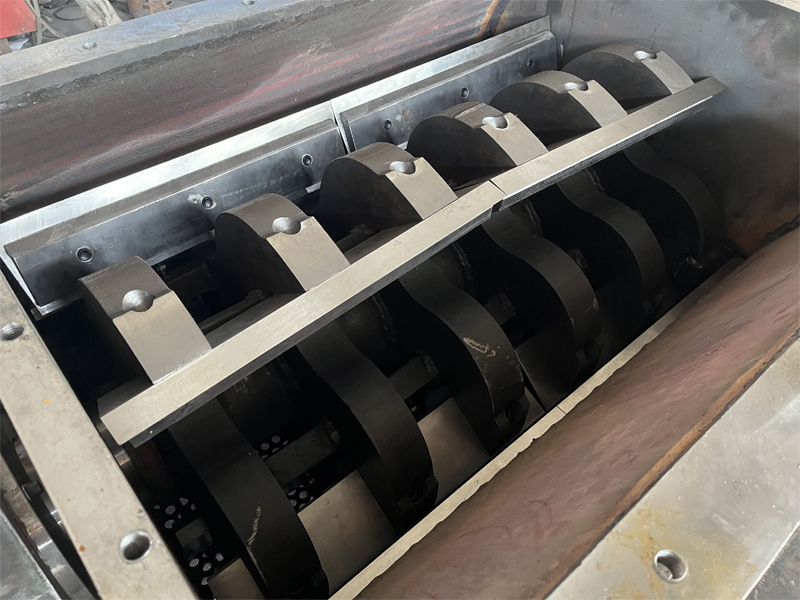

Features: oblique distribution of crushing knife, uniform shear force, wear-resistant crusher screen, coarse crushing spindle, to ensure rotary rigidity, to prevent clamping, high-speed rotary spindle is conducive to feeding and dehydration, greatly improve the effect and output.

Product features of plastic crusher:

1. The shaft is thickened, the rigidity is stronger, and the upper limit of crushing capacity is stronger than that of the same type of grinder.

2. Removable crusher blade can be used repeatedly after wear by sharpening machine.

3. The gap between the fixed knife and the moving knife is adjustable, and the discharge size can be controlled according to the needs.

Woven bag crusher operation method:

Put the woven bag into the crushing chamber, and under the interaction of the high-speed rotating knife and the fixed knife, the material is repeatedly cut to the required size to complete the crushing. The symmetrical distribution of the straight knife can effectively avoid grinding immobilization and entangling of the knife. The broken material falls through the screen and then enters the next processing process through the conveying equipment, which can also be centrally stored for reserve as shown in the figure above.

Crusher daily maintenance steps:

First: Read the safety operation manual before performing the following operations.

1. After the end of each shift, open the cover of the upper and lower silo, clean up the foreign matter inside the crusher, some corrosive liquid needs to be erased, if necessary, a layer of mechanical oil can be placed on the surface

2. After the blade is worn, use a knife sharpener for sharpening. Hand-grinding requires making fixtures to ensure flatness and be careful not to hurt the cutting edge

3. Add grease to bearings regularly

4. Check the tightness of the transmission belt regularly

5. Check the screw tightness regularly

In short, do a good job of spot inspection record, a small inspection a week, a full inspection a month, there are abnormalities reported in a timely manner, the reaction to the equipment engineer or contact the manufacturer, research shows that reasonable spot inspection can effectively reduce the number of equipment damage, basically small problems can be solved at the beginning.