One of the typical characteristics of post-consumer recycling (PCR) plastics is that the material is often at a high level of contamination.

There may be various impurities and foreign bodies in the recycling process of waste plastics pelletizing solution, such as paper, aluminum foil, sand, iron filings, copper wire, springs, wood chips, straw, silicone, rubber, and so on. These impurities and foreign bodies, if not filtered, will greatly reduce the quality of the recovered material, resulting in a decline in product quality or substandard products, and even damage to the pelletizing equipment. Therefore, melt filtration plays an indispensable role in the processing of waste plastics.

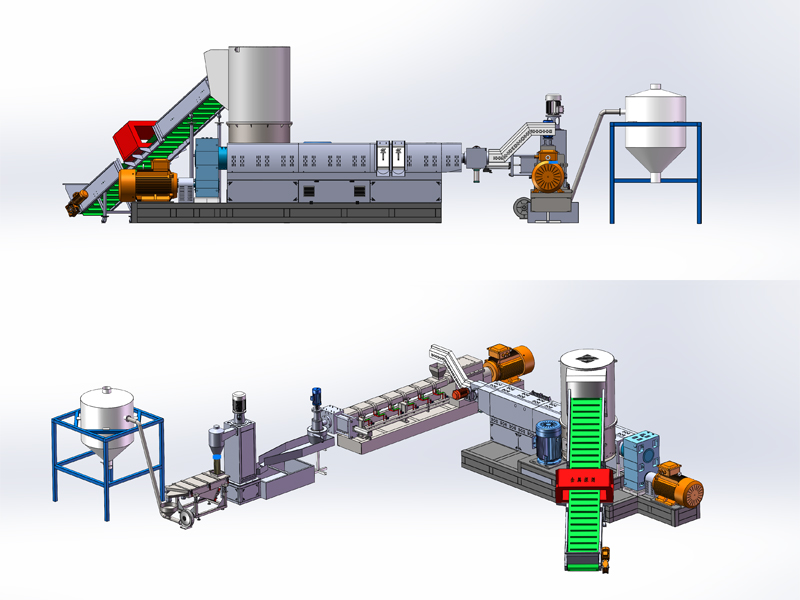

Recycled plastic filters can handle a variety of recycled plastics with pollutants up to 10%, including PE, PP, PS, ABS, HDPE, PET, etc. Single machine can achieve 2t/hr production capacity. Continuous automatic operation, to achieve a few weeks or months to change the network; Maximum filtration accuracy up to 150 mesh.

Fully automatic, high yield, continuous filtration:

RCDJ self cleaning pelletizing machine filter adopts PLC control, which can be fully automatic continuous production. No need to manually change the network frequently; with a diameter of 500 double filter board configuration, single effective filter area of up to

Effectively deal with the production of low melting materials

Laser filters on our film pelletizing line can be used to produce materials with low melting fingers and high impurities, such as various HDPE with melting fingers up to 0.3-0.7 and impurity content up to 5%-8%.

Higher filtration accuracy

The use of advanced CNC laser piercing machine can produce the highest filtration accuracy of 150 mesh filter. Under the same conditions of high output, the filtration accuracy of the same type of product on the market is generally 80 mesh or less.

Minimal material loss:

The RCDJ backflush laser filter can control the melt filtration loss rate to a minimum of 0.8% (depending on the impurity content of the material) through the precise adjustment of the filter plate speed, the slag screw speed and the scraper pressure system.

Longer service life:

The filter unit is rotated and the scraper is not moved. With the same type of filter in the market, the filter unit does not move, and the structural characteristics of the scraper rotation are completely different. Because of the different structure, our filters are equipped with a fully automatic hydraulic compensation system for scrapers. The pressure of the scraper is adjustable, and the best wear condition between the filter and the scraper can be achieved by precisely adjusting the cylinder pressure, and the service life of the filter can be increased by more than 25%. At the same time, the large filter area can effectively reduce the material pressure in front of the filter screen, and significantly improve the efficiency and life of the filter screen.

Continuous slagging:

Plastic recycling filter adopts continuous slag discharge design, and the impurity stays in the material cavity for a short time. The same type of equipment in the market is generally a slagging device with pressure or time control, which belongs to non-continuous slagging. There are limitations to the types and amounts of impurities that can be dealt with.