The truth about plastic recycling:

What kind of plastic can be recycled, how many times it can be recycled, how much can be recycled again, and which ones are actually recycled. All the truth about plastic recycling starts with the globally consistent plastic recycling labels.

In order to further improve the classification level of domestic waste, according to the relevant work requirements, and improve the recycling rate of domestic waste, the recyclables such as plastic waste are classified as follows:

Clearly include disposable plastic tableware, plastic supplies, express plastic packaging, plastic bags and other plastic products, as well as disposable paper cups, paper lunch boxes, Tetra Pak and other paper products as recyclables. When throwing in, all food residues should be poured out and thrown into the recyclables collection container.

There are various types and shapes of old plastics, and many recycling methods have been created in practice. Here are some examples for reference.

1. Film Recycling:

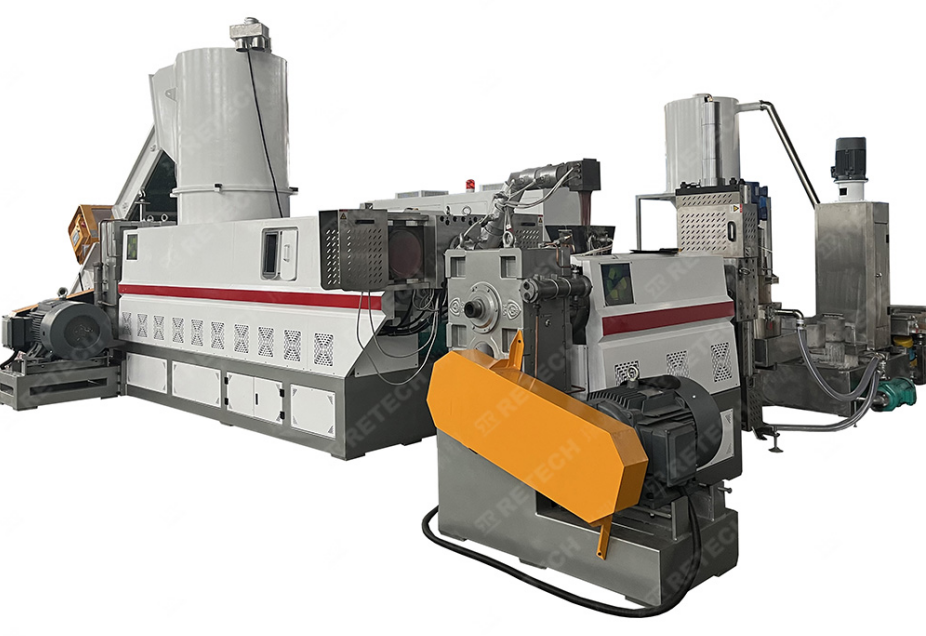

Film is one of the major types of plastic products, with a wide variety and generally short service life. It is one of the main types of recycling by crushing,washing,drying units.The PE film recycling equipment for processing films, there are plastic Film washing machine, plastic film granulator/pelletizing machine, etc.

2. PET HDPE Plastic Bottle recycling:

Bottles include refreshing beverage bottles, mineral PET water bottles, liquid food bottles, cosmetic bottles, etc. The materials used are polyethylene (PE), polyvinyl chloride (PVC), polyethylene terephthalate (polyester) ( PET), etc. Usually mineral water bottles are made of PVC or PET, carbonated beverage bottles are made of PET, refreshing drink bottles, liquid food bottles are made of PVC, PE, detergent bottles, cosmetic bottles, milk bottles, and lactic acid bacteria drinks are mostly made of PE.

The recycled bottles are usually manually sorted first, and then recycled according to different materials. At present, many technologies and equipment have been used for the recycling of various bottles. Such as:common PET bottle crushing washing and drying production line.

3. Styrofoam recycling:

Styrofoam is useful for polystyrene bead molding. Styrofoam plastics used for packaging of household appliances or frozen food packaging; there are also a few instant noodle bowls made of injection molded expandable polystyrene beads. These plastic products are bulky and cost a lot of tuition and fees, and their recycling has received special attention in

The main methods of polystyrene foam recycling are: granulation after volume reduction, crushing and use as various filling materials, cracking to oil or recovery of styrene and others.

4. Additional charges on plastic footwear:

Plastic footwear includes foamed and non-foamed sandals and slippers, and various plastic soles. The main materials are PVC, PE, PE/EVA, etc. Before additional collection and recycling, sorting must be carried out first, and manual sorting is generally the main method. After sorting, all kinds of waste footwear are recycled according to the type of material for utilization.

5. Polyurethane recycling:

There are various types of polyurethane, and its products include soft and hard foam plastics, thermoplastic elastomers and industrial products, which are widely used in automobiles, home appliances, chemicals, daily use and other fields. Recycling can be done separately by type.

6. Bakelite Recycling:

The main fillers of waste phenolic plastics are added to phenolic plastics, and the overall performance of materials added with waste phenolic plastics decreases.

Never has recyclability been more important than today

It is hoped that brand owners, manufacturers and packaging companies in the upstream of the plastic industry chain can participate in the project of plastic recyclable design, and jointly promote the introduction of the world's "Global Specification for Plastic Recyclable Design", so that our entire plastic The industrial chain has gradually become one, which is more conducive to the healthy development of domestic enterprises.