This process uses proven technology and successful management experience , through chemical transformation, physical separation , filtration and adsorption methods combine to achieve the purpose of governance standards , the process is mature and reliable , stable , easy to manage , easy maintenance.

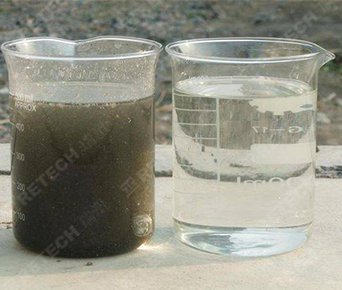

Workshop cleaning line generated waste water directly into wastewater regulation pool , the pool has a perforated pipe aeration ( if the user has air supply ) , to prevent sludge settling tanks , the pump automatically controlled by the level gauge , regular quantitative increase to wastewater from the lift pump processing reactor , PH meter by adding acid to adjust automatically to the optimum reaction condition PH (PH = 7.5-8.5), by the addition of PAC, PAM reaction effectively remove COD, SS, and other particles and other pollutants.