At present, the plastic recycling industry is very popular in the field of plastic. By recycling, waste plastic is converted into new plastic products that can be used for repeated use or becomes alternative fuels, which undoubtedly saves a lot of effective resources. The sustainable development of the ecological environment is achieved on the basis of the continuous economy.

For waste plastics, the traditional treatment method is incineration and landfill, but on the basis of environmental protection, this treatment method has been abandoned. If you want to recycle it, the plastic crushing and cleaning lines are currently widely selected and then again. Use the treatment method.

Below we mainly introduce several plastic processes for your reference:

Regenerative low-density polyethylene (LDPE) process:

LDPE, scientific name high -voltage polyethylene, generally refers to plastic packaging membrane. Such as: lining film, food packaging membrane, daily necessities, and large sheds in the woven bag.

Most of these membranes are primary colors, and there are light blue and black. It is best to separate the color sample before recovery.

You cannot put the low pressure membrane and PP film together, let alone put the OPP and PVC membranes. The recycling and re -use of LDPE is the regeneration LDPE process process. There are four main processes in the entire regeneration LDPE process:

1. Smash the process -it is better to crush with water and rinse. Because some good high -pressure membranes are well cleaned, it can be replaced without adding new materials. Therefore, pay attention to cleaning during the crushing process. It is best to roll again when the shattering is flowing to the sink, and the purpose is to be rushed further and clean.

2. Dry process -Generally, it is dried to dry the remaining water. If there is conditions, dry it. This can save electricity costs and improve the quality. Of course, pay attention to prevent the secondary pollution of the materials in drying.

3. Pelvic process -the particles made by the special extrusion machine have two basic uses: blow plastic film and injection again. The materials from the 60 -80 destination filter can be blown again; the materials from the 40 to 60 destination filter can meet the quality requirements of injection molding. Generally speaking, the high -pressure material blows the film again, and the good color blows is almost blowing black film and garbage bags, and the price after making injection plastic is lower.

4. Cut the granular process, generally cold water -this process must pay attention to the separation of the label when packing. A blowing plastic, an injection molding to avoid making mistakes. In addition, the packaging bag for blowing plastic must be plus the outer bag and inner lining to avoid secondary pollution.

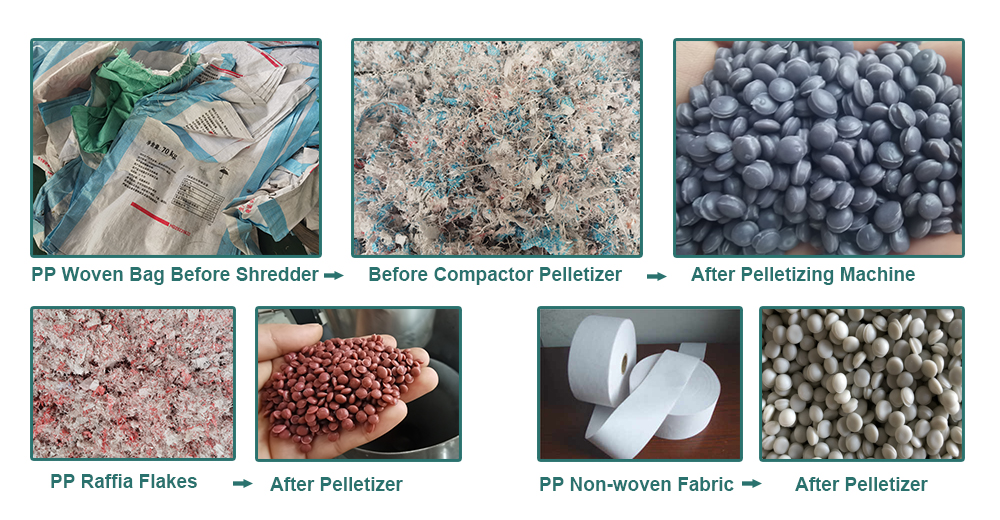

Polypropylene (PP) process:

Most of PP comes from daily necessities, plastic boxes, foot basins, buckets, rice baskets, plastic chairs, stools, woven bags, and other packaging woven fabrics, packaging bands, etc.

1. First separate the colors of various materials, because the separation will make users convenient, and the price can be increased.

2. Bringing water and rinse, dried the dried water, and then dried and packed the bag. Mix and add some color and assistant with mixing and machine.

3. Dedicated plastic machines are carried out on the car, but the temperature of the granularity should not be too high, and it is easy to get crispy, so be sure to pay attention to the temperature.

4. Cutting grains of water and cooling should be standard 3x

Regenerative polyethylene dilate (PET) process:

PET, scientific name polyethylene glycol, is a line -type thermoplastic plastic.

PET is usually a crystalline plastic. Due to the light quality, the PET bottle is light, it is not easy to break, and the energy consumption is low. It replaces some traditional packaging materials. It is widely used in food, drinks, cosmetics and other fields.

The recycling process of PET bottle slices is to separate the PET bottle body from the cover, label, etc., and then crush, clean, and dry.

It's specific process is as follows:

1. The first is to select the process: select a variety of PET bottles to select and divide the door category. Most of these trademarks are torn off the outside trademarks, and some of them are diluted membranes, and some polychloric chloride can be peeled first.

2. Powder process, rinse water during the crushing process to remove dirt in various PET bottles.

3. Put these fragments into the steam treatment device, add chip alkali, remove the greasy and other refractory impurities.

4. Wash it with water, dry the remaining water and bag. Then go to the vacuum oven for drying.

5. Spray wire, set, use hot water steam to extend, and then fixed.

ABS plastic process:

Most of ABS plastic is self -appliances, various daily necessities, and some mechanical widths.

ABS is more, computer cases, TV cases, instruments, car panels, decorative materials, picked this material, especially electroplating, painted paint color, etc. separate.

Chemical treatment, plating plating, and paint, but the paint must be cautious. Because there is a certain ratio of chemical medicinal water, it is necessary to use protective supplies and containers, otherwise it will cause damage and other events.

The cleaning slot is cleaned, and then dried, the color matching or the auxiliary material, the purpose is to improve the quality.

Dedicated extruder to make grains, but be sure to put the filter, but the filter is placed according to product requirements.

Regenerative polycarbonate (PC) process:

Polycarbonate, non -crystalline plastic, engineering plastic. Most of them come from textile accessories, car headlights, taillights, turning lights, candy production molds, discs, telecommunications equipment, photo equipment, etc.

1. First of all, the acquisition is selected for PC. It is transparent and opaque, blue, red, green, and black must be separated; there are also modified, such as most of the textile accessories are modified; such as discs and lamp heads are coated.

2. Washing various PCs, as the discretion process as the plate lamp head, and operate the same principle as ABS. Then dry it, classify it later, and send it to the production.

3.Some of thepc are more yellow and can produce porcelain white; transparent ones are still transparent; other colors can add color agents and material additives.

4.Dedicated squeezing machines, but the PC itself is easy to aging, so it cannot be returned many times. The granules must be cautious and cut into granules.

Regenerative Polyvinyl chloride (PVC) hard material process:

Most PVC hard fabrics come from building materials, plastic steel windows, electroplating hard boards, plastic valves, lowering pipes, and decorative materials for chemical plants.

1. First select the process and separate each color. These materials are divided into three types: white, gray, and black, but do not mix PP and PE.

2. Crush it to the crusher, but it is also crushed with water. Remove the pollution with water and dry it, and then dry it to prevent secondary pollution.

3. Mix and machine for ingredients, mix. If it is a white material, add the coloring agent, and put the additive according to the need to put it.

4. Dedicated PVC extruder for scraping and cooling bag labels to leave the factory.